Kaunas University of Technology (KTU) is a top technical university in the Baltic region with 9,000+ students and 2,500 staff. The University focuses on sustainable partnerships between science, business and industry, developing and implementing new ideas, innovations and inventions.

KTU had its beginning on 16 February 1922, when the University of Lithuania and its technical faculties were established. The development of Lithuanian scientific ideas continued in the first Lithuanian independent technical school of higher education (1950–1990, titled Kaunas Polytechnic Institute (KPI)). It was famous for the ultrasound and vibrotechnics laboratories, and scientific research of textiles. In 1990, KTU regained its status as a university and took a path of rapid reforms of studies and research. Today, KTU has 9 faculties, 8 institutes, 9 research centers, 23 student organizations, 12 student hostels, 7 art groups, and a Sports and Wellness Centre.

The Biomedical Engineering Institute

The project activities will take place at KTU Biomedical Engineering Institute (BMII). The Institute is focused on research and development of clinical and biomedical engineering technologies, in particular medical ultrasound and biomedical signal processing algorithms. Recent European-funded projects include EU and Lithuanian Research Council-supported projects on ultrasound-based tissue elastography, heart arrhythmia, stroke, and haemodialysis patient monitoring.

KTU has been conducting research in the biomedical engineering field for almost 40 years. BMII was established in 2000 and has started to take an active part in international research projects. Today, as part of both study and research processes at KTU, BMII is competitive on national and international levels in biomedical engineering, such as biomedical electronics, sensors, wearable systems, ultrasound diagnostics, and signal and image processing.

Key competencies

KTU BMII contributes experience in sensors and algorithms for biosignals processing areas:

- Algorithms for processing and characterisation of biomedical signals: electrocardiograms (ECG), electromyograms (EMG), electroencephalograms (EEG), photoplethysmograms (PPG), bioimpedance spectroscopy (BIS) and ultrasound echoscopy (US).

- Specific algorithms: heart arrhythmia detection, physical activity characterization, pulse wave analysis, biomedical signal quality indexes, phenomenological signal modeling.

- Biomedical sensors: biopotential electrodes, biooptical sensors.

- Biomedical electronics: front-ends, microcontrollers, wireless connectivity.

- Secure management of physiological signals and data.

The research outputs are applied for different fields in medical practice, such as cardiology, ophthalmology, neurology and for solving general medical and population problems, such as primary and preventive healthcare, rehabilitation, and healthy aging.

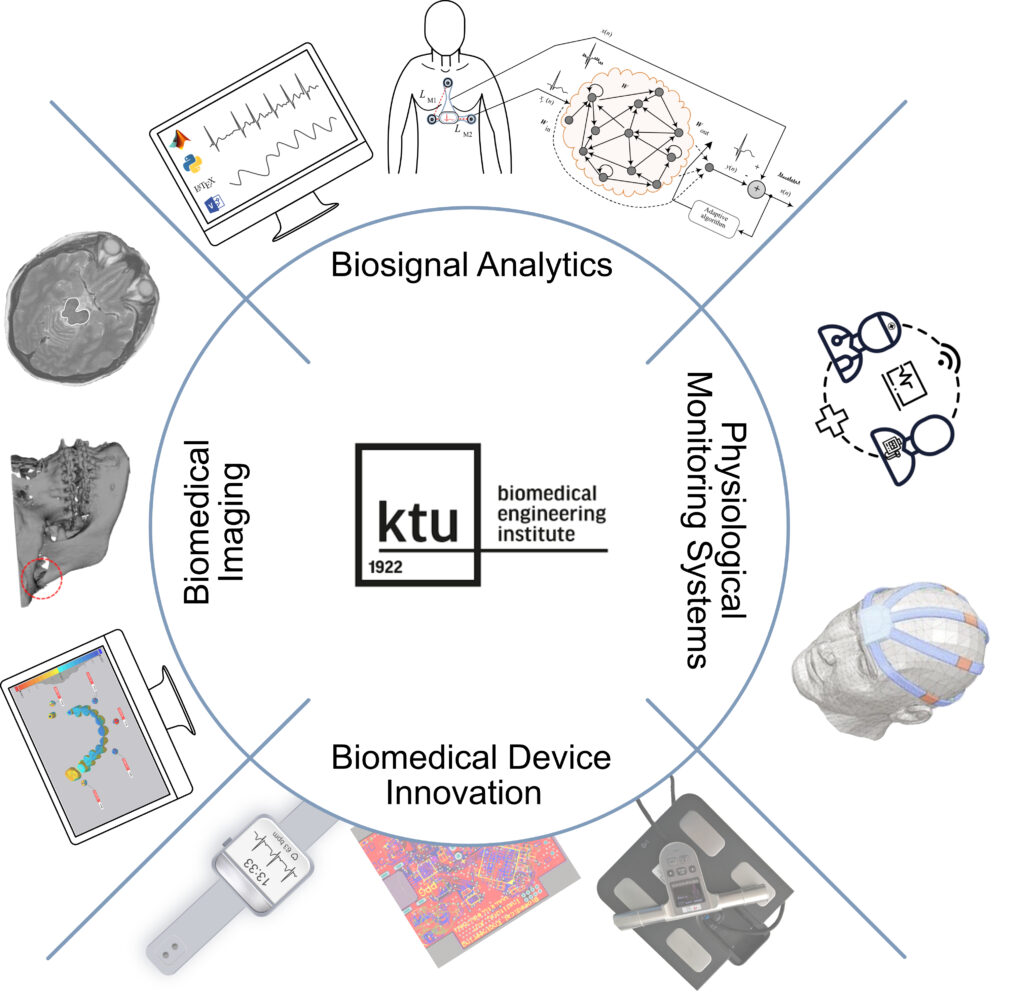

Vision and structure of the Institute

To foster the advancement and dissemination of knowledge and technologies, facilitate interdisciplinary research in biomedical engineering, and contribute to international studies, BMII runs four laboratories:

- Biosignal Analytics Laboratory: focuses on processing, modeling, and integrating multimodal data to extract clinically relevant information.

- Biomedical Imaging Laboratory: concentrates on processing, analyzing, and parametrizing medical images to enhance their informativeness and clinical value.

- Biomedical Device Innovation Laboratory: specializes in designing prototypes of biomedical devices and developing algorithms for biosignal parameterization and analysis.

- Physiological Monitoring Systems Laboratory: concentrates on the study and evaluation of medical prototypes and devices.

Contribution to the ThrombUS+ project

KTU BMII has extensive experience in the development of biomedical sensors, signal processing algorithms, and biosignal databases. They will lead the entire Sensor System Integration Work Package (WP6) and also contribute to 9 tasks in other work packages, including ultrasonic thrombus detection and characterization, participating in the execution of 15 tasks overall. These tasks will include: developing functional and technical requirements for the system, designing the tissue, compression actuator, creating the limb activity sensor, Specifying product requirements, defining testing methodologies, and implementing security and privacy solutions for the integrated system.